Introduction to typical application scenarios of displacement sensors in six industries

Dec 19, 2024

Introduction

Sensors are an indispensable driving force in today's technological field, hailed as the neural tentacles of modern intelligence, and an important part of the era of the Internet of Everything. Next, we will introduce the typical application scenarios of displacement sensors in various industries.

Semiconductor Industry

The application of displacement sensors in the semiconductor industry is very extensive, mainly used for measuring the tiny displacement in semiconductor equipment. Here are some applications of displacement sensors in the semiconductor industry:

1.Wafer Measurement: Wafers are the most basic material in the semiconductor manufacturing process, and their flatness and thickness greatly affect the performance of the final product. Displacement sensors can measure the flatness and thickness of wafers, thereby ensuring product quality.

2.Robotic Arm Control: In semiconductor manufacturing, robotic arms are used to transfer wafers from one process to another. The accuracy of robotic arms greatly affects product performance. Displacement sensors can measure the displacement of robotic arms, thereby controlling the motion accuracy of robotic arms.

3.Inspection Tools: Various inspection tools are required in semiconductor manufacturing to test the performance and quality of products. Displacement sensors can measure the displacement of inspection tools, thereby ensuring testing accuracy.

4.Cleaning Equipment: Various cleaning equipment are required during the semiconductor manufacturing process to clean wafers and equipment. Displacement sensors can measure the displacement of cleaning equipment, thereby controlling the effectiveness and duration of the cleaning process.

New energy lithium battery industry

Displacement sensors are widely used in the new energy industry, mainly for measuring and controlling the position and motion state of various new energy equipment. Here are some applications of displacement sensors in the new energy industry:

1.Wind Power Generation: Wind turbines need to adjust the angle of their blades according to wind speed and direction to capture wind energy to the greatest extent. Displacement sensors can measure the position and angle of the blades and control the operation state of the wind turbines.

2.Solar Power Generation: Solar panels need to adjust their angle and orientation according to the position of the sun and the intensity of sunlight to capture solar energy to the greatest extent. Displacement sensors can measure the position and angle of the panels and control the operation state of the panels.

3.Electric Vehicles: Electric vehicles need to adjust the position and angle of the wheels according to vehicle speed and road conditions to ensure driving stability and safety. Displacement sensors can measure the position and angle of the wheels and control the operation state of the wheels.

4.Hydrogen Energy: Hydrogen energy needs to adjust the operating state and output power of hydrogen fuel cells according to the flow and pressure of hydrogen gas. Displacement sensors can measure the flow and pressure inside the hydrogen fuel cells and control their operating state.

5.In summary, displacement sensors play a crucial role in the new energy industry. They can improve the efficiency and reliability of energy equipment, reduce operating costs and failure rates, and at the same time increase the efficiency of energy use and environmental friendliness.

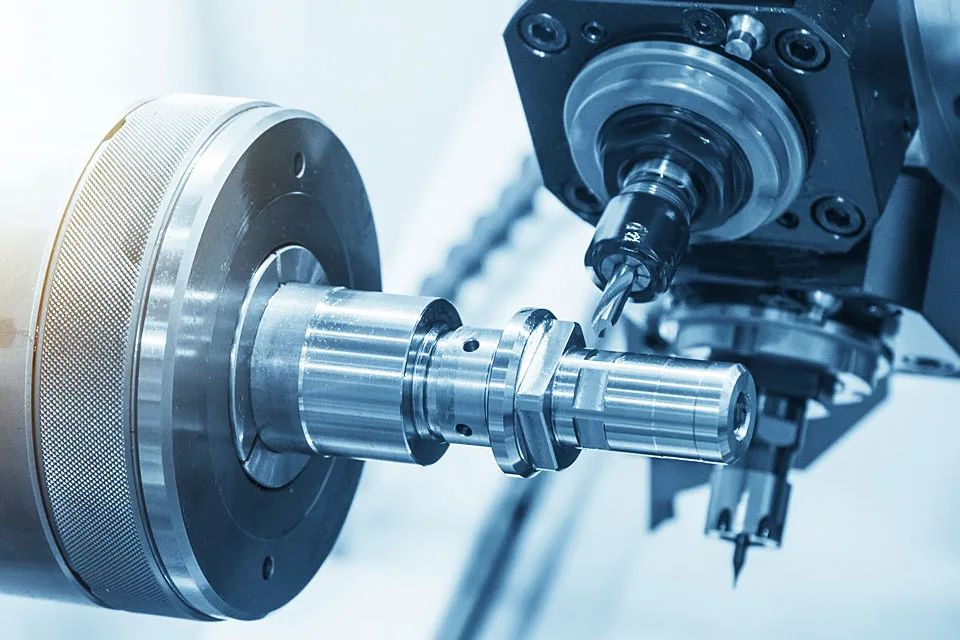

Precision Manufacturing Industry

Displacement sensors are widely used in the precision manufacturing industry, mainly for measuring and controlling the position and movement status of various precision equipment. Here are some applications of displacement sensors in the precision manufacturing industry:

1.Machine Tool Processing: Machine tool processing requires adjusting the position and movement trajectory of the tool according to the size and shape of the parts to meet precision requirements. Displacement sensors can measure the position and movement trajectory of the tool and control the operation status of the machine tool.

2.Precision Measurement: Precision measurement requires adjusting the position and angle of the measuring instrument according to the size and shape of the object being measured to meet precision requirements. Displacement sensors can measure the position and angle of the measuring instrument and control the accuracy and precision of the measurement process.

3.Optical Equipment: Optical equipment requires adjusting the position and orientation of lenses according to the length and angle of the optical path to meet precision requirements. Displacement sensors can measure the position and orientation of the lenses and control the accuracy and precision of the optical path.

4.Electronic Devices: Electronic devices require adjusting the position and connection method of electronic components according to the size and shape of the circuit board to meet precision requirements. Displacement sensors can measure the position and connection method of electronic components and control the accuracy and precision of the circuit board.

Precision Manufacturing Industry

Displacement sensors are widely used in the precision manufacturing industry, mainly for measuring and controlling the position and movement status of various precision equipment. Here are some applications of displacement sensors in the precision manufacturing industry:

1.Machine tool processing: Machine tool processing requires adjusting the position and movement path of the tool according to the size and shape of the parts to meet precision requirements. Displacement sensors can measure the position and movement path of the tool and control the operation status of the machine tool.

2.Precision measurement: Precision measurement requires adjusting the position and angle of the measuring instrument according to the size and shape of the object being measured to meet precision requirements. Displacement sensors can measure the position and angle of the measuring instrument and control the accuracy and precision of the measurement process.

3.Optical equipment: Optical equipment requires adjusting the position and orientation of lenses according to the length and angle of the optical path to meet precision requirements. Displacement sensors can measure the position and orientation of the lenses and control the accuracy and precision of the optical path.

4.Electronic devices: Electronic devices require adjusting the position and connection method of electronic components according to the size and shape of the circuit board to meet precision requirements. Displacement sensors can measure the position and connection method of electronic components and control the accuracy and precision of the circuit board.

3C Electronics Industry

Displacement sensors are widely used in the 3C electronics industry, mainly for measuring and controlling the position and movement status of various electronic devices. Here are some applications of displacement sensors in the 3C electronics industry:

1.Mobile phones and tablets: Mobile phones and tablets need to adjust the screen position and angle according to user operation requirements to provide the best user experience. Displacement sensors can measure the screen position and angle and control the movement status of the screen.

2.Cameras and camcorders: Cameras and camcorders need to adjust the lens position and focal length according to shooting requirements to capture the best image effects. Displacement sensors can measure the lens position and focal length and control the movement status of the lens.

3.Game consoles and VR devices: Game consoles and VR devices need to adjust the game screen and virtual reality experience according to user operation requirements to provide the best gaming experience. Displacement sensors can measure the position and angle of the device and control the game screen and virtual reality effects.

Municipal inspection industry

In the municipal inspection industry, displacement sensors are widely used to measure and monitor the displacement and deformation of public infrastructure, thereby enhancing the safety and reliability of urban construction. The following are applications of displacement sensors in municipal inspections:

1.Bridge Inspection: Displacement sensors can measure the displacement and deformation of bridge components such as piers, beams, and slabs, as well as the vibration and oscillation of bridges, to promptly identify and repair potential safety hazards.

2.Tunnel Inspection: Displacement sensors can measure the displacement and deformation within tunnels, as well as the vibration and oscillation of tunnels, to promptly identify and repair potential safety hazards.

3.Building Inspection: Displacement sensors can measure the displacement and deformation of buildings, as well as the vibration and oscillation of buildings, to promptly identify and repair potential safety hazards.

4.Subway Inspection: Displacement sensors can measure the displacement and deformation of subway tunnels and stations, as well as the vibration and oscillation of subways, to promptly identify and repair potential safety hazards.

Academic and Scientific Research Industry

Displacement sensors are widely used in academic and scientific research to measure various physical quantities of displacement and change. Here are some applications of displacement sensors in academic and scientific research:

1.Material Research: Displacement sensors can measure the expansion, contraction, and deformation of materials, thereby studying the properties and behaviors of materials.

2.Structural Mechanics: Displacement sensors can measure the deformation and displacement of structures, thereby studying the mechanical properties and stress distribution of structures.

3.Biomedicine: Displacement sensors can measure the displacement and deformation of biological tissues, thereby studying the mechanical properties and physiological processes of biological tissues.

4.Environmental Monitoring: Displacement sensors can measure changes in environmental physical quantities such as crustal deformation, building vibrations, and ocean waves, thereby studying fields such as geophysics, building engineering, and marine science.

5.Robot Control: Displacement sensors can measure the position and posture changes of robots, thereby controlling the movement and operation of robots.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Oct 11, 2024

Shanghai Vision Expo | Highlights of TronSight

Oct 17, 2023

20 Trends in Sensors Over the Next Few Years