Spectral Confocal Displacement Sensors Excel in Measuring the Thickness of Glass Substrates

Sep 02, 2022

Glass substrates are one of the essential components of liquid crystal displays, with one LCD using two glass substrates, each serving as the bottom glass substrate and the color filter substrate. The quality of the glass substrates is crucial for controlling the screen resolution, light transmittance, thickness, weight, viewing angle, and other parameters of the finished display panel. Glass substrates are a fundamental component of the LCD assembly. This is a method for producing thin glass lenses with an extremely flat surface. Currently, the commercially used glass substrates have core thicknesses of 0.7 mm and 0.5 mm, and are moving towards the production of ultra-thin (such as 0.4 mm) thicknesses. Generally, one TFT-LCD panel requires two glass substrates, one for the bottom glass substrate and the other for the color filter (COLOR FILTER) substrate.

Only four companies, including Corning in the United States and Asahi Glass in Japan, can provide large-sized glass substrates for LCDs. Among them, Corning holds a 51% market share, while Asahi Glass holds a 28% market share. Only these two companies can supply glass substrates for production lines of the 5th generation and above. Although glass substrates only account for 6%-7% of the production cost of TFT-LCDs, the technological monopoly in the market makes glass substrate products a dominant component in the upstream raw materials of TFT-LCDs. Chinese companies such as China Star Optoelectronics Technology and Dongxu should receive special support and encouragement for their self-initiated TFT-LCD glass projects.

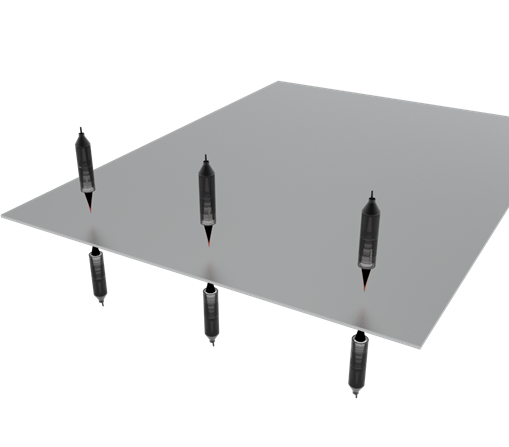

Because the glass substrate is very thin and the thickness specifications are strictly regulated, usually with a tolerance of 0.01mm, it is crucial to accurately measure the thickness, expansion and contraction, and flatness of laminated glass. Choosing the high-precision spectral confocal displacement sensor independently developed by Chuangshi Intelligence can very well address this challenge. A single measurement can complete the collection of relative height values and thickness coefficients. Moreover, by using multiple sensors for measurement simultaneously, not only is efficiency improved, but also secondary damage caused by contact measurement is prevented. Currently, the TronSight TS-C series spectral confocal displacement sensor is highly sought after and trusted by many glass substrate manufacturers. Users have given 100% positive feedback. It is believed that in the future, TronSight can provide comprehensive precision measurement solutions for more industries!

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

Oct 11, 2024

Shanghai Vision Expo | Highlights of TronSight

Oct 17, 2023

20 Trends in Sensors Over the Next Few Years