AUTO04. Foam Board Thickness Measurement: Challenges and High-Precision Solutions

Sep 08, 2025

Foam Board Thickness Measurement: Challenges and High-Precision Solutions

What is Foam Board Thickness Measurement and Why is it So Important?

Foam board, also known as foam core board, is a versatile material prized for its lightweight, high strength, and excellent thermal and sound insulation properties. It's widely used in construction, packaging, advertising, and manufacturing. The thickness of foam board is a critical parameter that determines its performance and suitability for various applications. Whether it's providing insulation in a building or cushioning for protective packaging, precise thickness is non-negotiable.

Comparison of Common Measurement Methods

Traditional methods for measuring foam board thickness often suffer from low efficiency, susceptibility to human error, and insufficient accuracy. Here's a comparison of common methods and their drawbacks:

The Principle and Process of Chromatic Confocal Measurement

The Tronsight TS-C series chromatic confocal displacement sensor uses advanced white light chromatic confocal technology. Its working principle is based on the dispersion of light: a beam of broadband white light is focused onto the surface of the object. Only the specific wavelength of light that is perfectly focused on the object's surface is reflected back to the sensor with the highest intensity. By analyzing the spectrum of the reflected light, the sensor can precisely calculate the distance from the sensor to the object's surface.

The entire measurement process is both efficient and precise:

-

Beam Focusing: The probe focuses a beam of broadband white light onto the foam board's surface.

-

Reflected Light Collection: Only the light corresponding to a specific wavelength is reflected back to the sensor with optimal intensity.

-

Spectral Analysis: The sensor's internal spectrometer analyzes the spectrum of the reflected light to determine the peak wavelength.

-

Distance Calculation: Based on the established correlation between peak wavelength and distance, the exact distance from the probe to the foam board's surface is calculated.

-

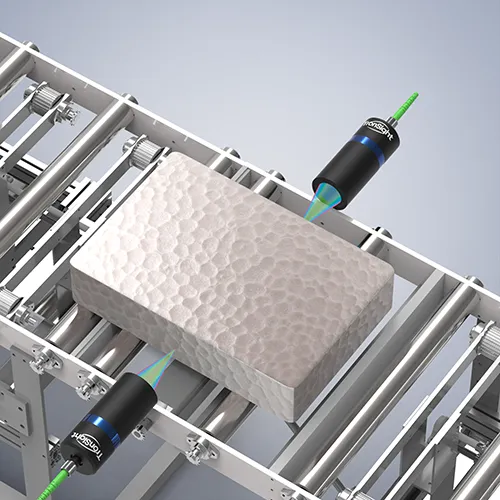

Thickness Measurement: By placing two probes on the top and bottom sides of the foam board and synchronizing their measurements, the precise thickness is obtained through simple mathematical subtraction.

Tronsight’s Solution for Foam Board Thickness Measurement

Tronsight’s TS-C series chromatic confocal displacement sensor provides an unparalleled solution for foam board thickness measurement.

Product Advantages:

-

High Precision: Provides nanometer-level accuracy, ensuring the absolute reliability of your thickness data.

-

Non-Contact: Completely avoids the deformation caused by traditional contact-based methods, guaranteeing true and accurate measurements.

-

High Speed: Supports a sampling rate of up to 32kHz, meeting the demands of high-speed production lines.

-

Multi-Channel Full Synchronization: Supports 16-channel full synchronization and is compatible with the EtherCAT bus protocol, allowing for easy integration into automated production lines.

-

Strong Adaptability: The probe's minimum outer diameter is only Ф3.8mm, making it easy to install in confined spaces. It is also compatible with high-temperature and vacuum environments and can effectively measure transparent or semi-transparent materials like multi-layer glass.

Our solution not only enhances your product quality control but also significantly boosts production efficiency and reduces labor costs.

Learn More About Tronsight Products or Consult an Expert

-

Product Recommendation: Explore how the Tronsight TS-C series chromatic confocal displacement sensor can transform your production process.

-

Contact Us: Consult with our technical experts today to receive a customized solution for your specific application.

Leave a message:

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor