THINFILMO2. The Art and Science of Multilayer Film Thickness Measurement

Sep 09, 2025

The Art and Science of Multilayer Film Thickness Measurement

Why Multi-Layer Films Are Everywhere and Why They Need Precision

Multilayer films are essential to advanced products, from flexible displays and smart windows to high-performance solar cells and semiconductor wafers. Each layer is engineered for a specific function—anti-reflection, insulation, optical filtering, or protection.

In industries like electronics, optics, semiconductors, and new energy, the thickness of every layer is mission-critical. Even a single nanometer of deviation can compromise performance, reduce efficiency, or shorten product lifespan. That’s why multi-layer film thickness measurement with nanometer-level precision is now a non-negotiable step in quality control and process optimization.

It’s no longer enough to measure just the total stack thickness. Manufacturers must simultaneously and non-destructively measure each individual layer—up to five or more—to ensure flawless product integrity and yield.

Common Applications Requiring Multi-Layer Measurement

-

Flexible Displays & Touchscreens: Multi-layer coatings for anti-reflection, scratch resistance, and touch sensitivity.

-

Solar Cells: Semiconductor and anti-reflective layers that require nanometer-level precision for maximum energy conversion.

-

Semiconductor Manufacturing: Complex stacks of dielectric, conductive, and resistive layers deposited with extreme accuracy.

-

Optical Coatings: Multi-layer films on lenses, mirrors, and filters for precise optical performance.

-

Medical Devices: Functional coatings on implants and stents, where precision directly impacts safety.

Why Traditional Methods Fall Short

| Method | Pros | Cons |

|---|---|---|

| Ellipsometry | High resolution | Complex setup, vibration-sensitive, not inline-capable |

| Spectroscopic Reflectometry | Fast, non-contact | Accuracy limited by material stack and refractive index, struggles with opaque films |

| SEM | Direct visual of layers | Destructive, expensive, lab-only, very slow |

| Tronsight Interferometric Sensors | Non-contact, high-speed, measures up to 5 layers simultaneously | Each series optimized for specific material types |

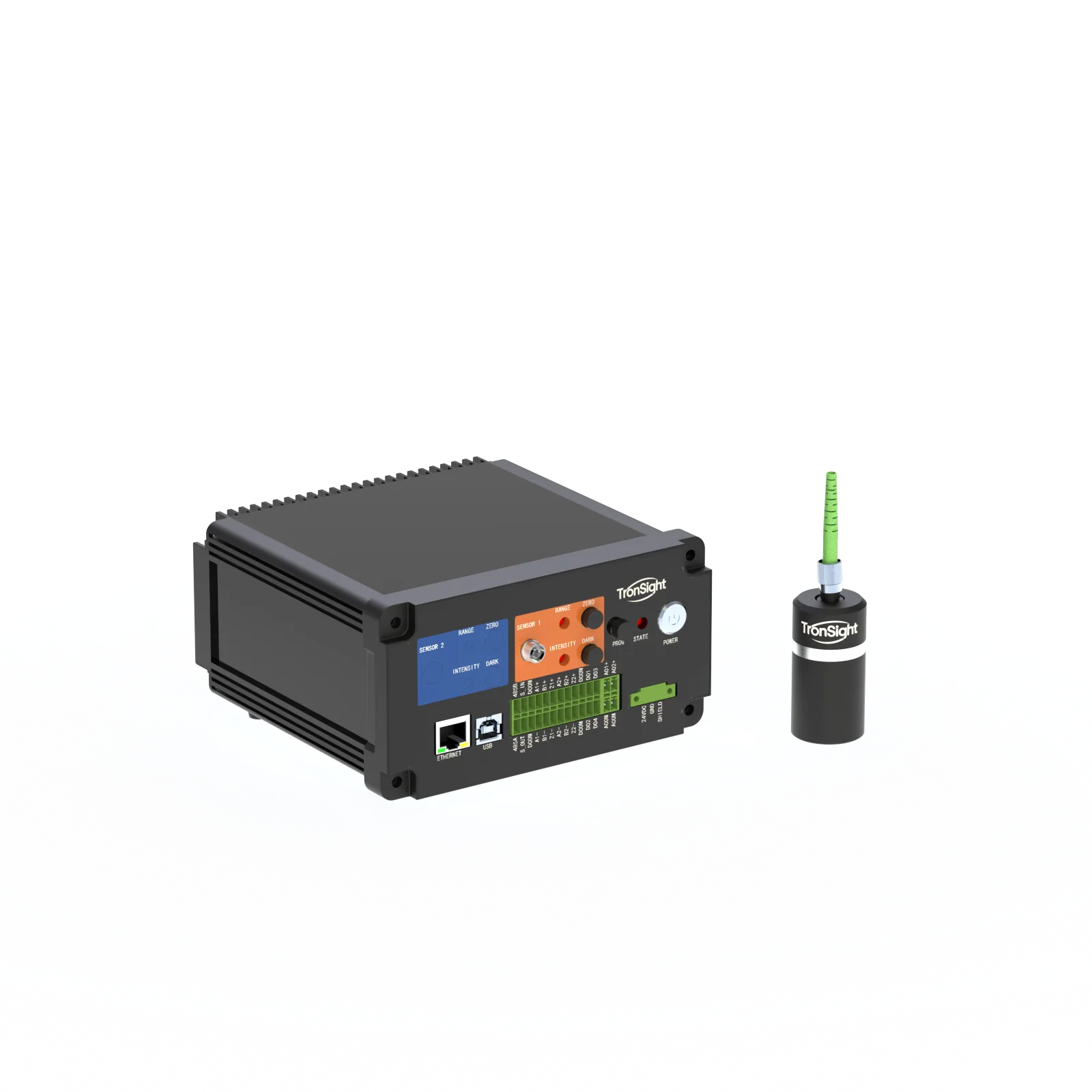

Tronsight’s Unified Approach to Multilayer Precision

At Tronsight, we deliver a portfolio of advanced interferometric thickness sensors designed to solve every multilayer measurement challenge. All series share three pillars: nanometer precision, real-time speed, and non-contact stability—enabling up to five layers measured simultaneously in both R&D and inline production.

TS-IV Series: White Light Interferometric Thickness Sensor

Optimized for transparent and translucent multilayer stacks, the TS-IV analyzes interference peaks from each interface to separate and measure every layer.

Key Features:

-

1 nm repeatability, ±20 nm linear accuracy for nanometer-level precision.

-

Up to 10 kHz sampling speed for inline inspection of transparent films.

-

1–2500 µm measurement range, covering ultra-thin coatings to thick laminates.

-

Ideal for display films, optical coatings, glass laminates.

TS-IR Series: Infrared Interferometric Thickness Sensor

When visible light can’t penetrate, the TS-IR provides the breakthrough. Using infrared light, it measures internal layers in opaque or dark materials—indispensable in semiconductor manufacturing.

Key Features:

-

40 kHz sampling speed, 2 nm repeatability—built for high-volume fabs.

-

Infrared penetration enables measurement on silicon, SiC, GaAs, and other IR-transparent materials.

-

Perfect for opaque/dark multilayer stacks where white-light sensors fail.

TS-R Series: Reflective Film Thickness Sensor

Engineered for ultra-thin reflective films, the TS-R achieves unmatched accuracy for nanometer-scale monitoring.

Key Features:

-

Minimum 20 nm measurable thickness, ideal for the thinnest coatings.

-

±1 nm accuracy, 0.05 nm repeatability—the highest stability in its class.

-

Up to 100 Hz sampling speed for real-time process control.

-

Suited for optical films, functional coatings, semiconductor thin films.

Tronsight: Your Partner in Multi-Layer Precision

With the TS-IV, TS-IR, and TS-R series, Tronsight empowers industries to achieve reliable, non-destructive, real-time multilayer film thickness measurement.

Our brand promise—Precision Measurement Expert—means you’re not just buying hardware; you’re partnering with experts who understand your application and deliver tailored solutions.

👉 Discover the right interferometric thickness sensor for your multilayer application today. Contact Tronsight for a consultation.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor