AUTO05.Optimize Production: Real-Time Rolling Thickness Control with Tronsight Sensors

Sep 08, 2025

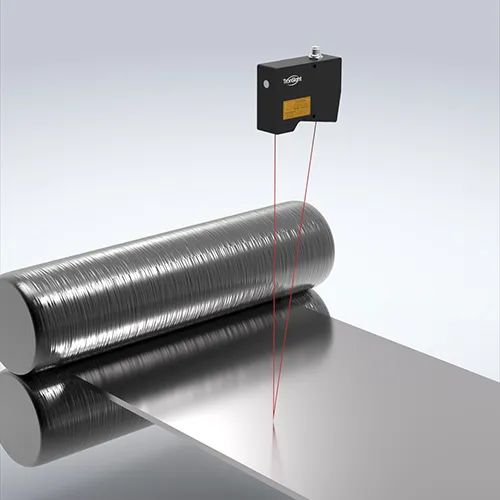

Real-Time Rolling Thickness Control with Tronsight Sensors

What is Rolling Thickness Measurement and Why is it Important?

Rolling is a metalworking process used to reduce the thickness and achieve a uniform cross-section of materials like steel, aluminum, and plastics. Rolling thickness measurement is the critical process of continuously monitoring and controlling the thickness of the material as it passes through the rollers. This is vital for maintaining product quality, ensuring material consistency, and meeting stringent industry standards. Inaccurate measurements can lead to wasted materials, product defects, and costly production downtime.

Comparison of Common Measurement Methods

While various methods exist for rolling thickness measurement, they each have their own limitations. Here's a comparison of common methods and their trade-offs:

The Principle and Process of Laser Triangulation Measurement

Tronsight’s TS-P series laser triangulation displacement sensor offers a superior solution. The principle of laser triangulation is based on geometric optics. A laser beam is projected onto the target surface at a specific angle. The light reflected from the surface is then collected by a receiving lens and focused onto a position-sensitive detector (PSD) or a CMOS/CCD array. As the target's distance changes, the spot of reflected light shifts on the detector.

The process is fast and precise:

-

Laser Projection: A focused laser beam is projected onto the surface of the rolling material.

-

Light Reflection: The laser spot reflects off the material's surface.

-

Sensor Detection: The reflected light is captured by the sensor's receiving lens and focused onto the detector.

-

Position Calculation: The detector calculates the exact position of the reflected light spot.

-

Distance Measurement: Based on the known triangulation geometry, the sensor's internal processor calculates the precise distance to the material surface. By using two sensors—one on the top and one on the bottom of the material—the exact thickness is determined.

Tronsight's Solution for Rolling Thickness Measurement

The Tronsight TS-P series laser triangulation displacement sensor is specifically engineered for demanding applications like rolling thickness measurement.

Key Features and Benefits:

-

Unmatched Speed: A remarkable 160kHz sampling rate allows for continuous, real-time monitoring of fast-moving materials.

-

Exceptional Accuracy: With a linear accuracy of ±0.02% of F.S. and repeatability of 0.02μm, the TS-P series ensures the highest level of precision and quality control.

-

Broad Measurement Range: A versatile measurement range from 2mm to 2000mm covers a wide variety of materials and applications.

-

Advanced Customization: The built-in controller and a customizable design allow for in-depth customization of line width, light source, wavelength, and structural dimensions to perfectly match your specific needs.

-

Robust Integration: The built-in controller simplifies setup and integration into your existing production line, making it a truly plug-and-play solution for industrial automation.

Our solution significantly enhances your manufacturing process by providing accurate, reliable, and real-time thickness data, preventing defects and optimizing material usage.

Learn More or Consult an Expert

-

Product Recommendations: Discover how the Tronsight TS-P series can transform your rolling thickness measurement process.

-

Contact Us: Speak with one of our technical experts to receive a customized solution for your specific application.

Leave a message:

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor