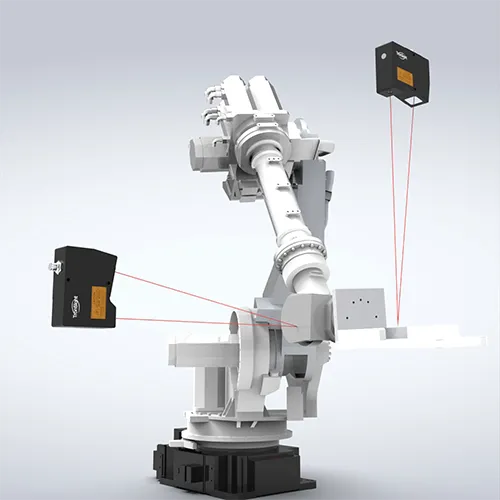

AUTO07.Ensuring Absolute Precision in Robotic Arm Fixture Positioning

Sep 08, 2025

What is Robotic Arm Fixture Positioning Measurement and Why is it Critical?

In modern manufacturing, robotic arms are the backbone of automation, performing a wide range of tasks from welding and assembly to quality inspection. A key challenge is ensuring that the robotic arm's end-effector—the tool or gripper—is positioned with extreme accuracy relative to the workpiece, which is typically held by a fixture. Robotic arm fixture positioning measurement is the process of precisely locating this workpiece and the fixture in 3D space.

Why is this so important? Any misalignment, even at the micron level, can lead to costly errors like poor weld quality, misaligned parts, or defects in the final product. Precise measurement guarantees that the robotic arm performs its task exactly as programmed, improving product quality, reducing waste, and boosting overall production efficiency.

Common Methods for Fixture and Positioning Measurement

While various methods exist to measure fixture and positioning, they each have their own limitations, especially when high speed and precision are required.

| Measurement Method | Pros | Cons |

| Vision Systems | Non-contact, can measure a large area | High software and hardware costs; performance is sensitive to lighting conditions and surface contrast |

| Laser Trackers | Very high accuracy over a large volume | High cost, slow setup time, and not suitable for continuous in-line measurement |

| Contact Probes | High accuracy for a single point | Slow, requires physical contact, can't be used for real-time monitoring of a dynamic process |

| Laser Triangulation Sensors | Non-contact, high-speed, high-precision, flexible for in-line use | Performance can be affected by the material's surface reflectivity and color |

The Principle and Process of Laser Triangulation for Positioning

The Tronsight TS-P series laser triangulation displacement sensor provides a powerful, non-contact solution for this challenge. Its principle is based on geometric optics. A laser beam is projected at a precise angle onto the fixture or workpiece. The light reflected from the target surface is then captured by a receiving lens and focused onto a position-sensitive detector (PSD) or a CMOS/CCD array. As the target's position changes, the spot of reflected light shifts on the detector.

The measurement process is both fast and precise:

-

Laser Projection: The sensor projects a focused laser line or spot onto a key point of the fixture or workpiece.

-

Light Reflection: The laser spot reflects off the target's surface, and its position changes based on the distance from the sensor.

-

Sensor Detection: The reflected light is captured by the sensor's lens and focused onto the detector. The detector precisely pinpoints the location of the light spot.

-

Distance Calculation: Based on the known triangulation geometry, the sensor's internal processor converts the light spot position into a precise distance measurement. By integrating the sensor with the robotic arm's control system, you can use this real-time distance data to verify or correct the arm's position.

Tronsight's Solution for Robotic Arm Positioning

The Tronsight TS-P series laser triangulation displacement sensor is specifically engineered to meet the demanding requirements of robotic automation.

Key Features and Benefits:

-

Unmatched Speed: With a remarkable 160kHz sampling rate, the sensor provides real-time position data, making it ideal for high-speed robotic processes where microseconds matter.

-

Exceptional Accuracy: An outstanding ±0.02% of F.S. linear accuracy and 0.02μm repeatability ensure that every positioning check is reliable, guaranteeing superior quality control.

-

Broad Measurement Range: A versatile measurement range from 2mm to 2000mm allows a single sensor to be used for a wide variety of robotic tasks and fixtures.

-

Advanced Customization: The built-in controller and a customizable design allow for in-depth customization of line width, light source, wavelength, and structural dimensions to perfectly match your specific needs.

-

Robust Integration: The compact, lightweight sensor head and integrated controller simplify setup and integration directly onto the robotic arm, making it a truly plug-and-play solution for industrial automation.

Our solution significantly enhances your robotic system's performance by providing the high-speed, high-precision feedback necessary for flawless execution, ensuring your automation investment delivers maximum value.

Learn More or Consult an Expert

-

Product Recommendations: Discover how the Tronsight TS-P series can enhance your robotic positioning and quality control.

-

Contact Us: Speak with one of our technical experts to receive a customized solution for your specific application.

Leave a message:

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor