AUTO06.Mastering Metal Surface Roughness Measurement with High-Speed Laser Technology

Sep 08, 2025

Mastering Metal Surface Roughness Measurement with High-Speed Laser Technology

What is Metal Surface Roughness Measurement and Why is it Critical?

Metal surface roughness refers to the finely spaced irregularities on a metal surface, which are a result of the manufacturing process. It's a key parameter in determining a component's quality and functionality. A specific roughness is often required for optimal performance, affecting friction, wear, adhesion, and overall lifespan of parts. In industries ranging from automotive and aerospace to medical devices and electronics, precise measurement of surface roughness is essential for ensuring product quality, predicting part performance, and maintaining manufacturing standards.

Common Methods for Measuring Surface Roughness

While several methods exist to measure surface roughness, they vary significantly in speed, accuracy, and suitability for industrial applications.

| Measurement Method | Pros | Cons |

| Stylus Profilometer | High accuracy, well-established standard | Slow, contact-based which can damage soft surfaces, not suitable for online or in-line measurement |

| Optical Interferometry | Non-contact, very high resolution | Extremely sensitive to vibration, slow, high cost, typically for laboratory use |

| Laser Triangulation Sensor | High-speed, non-contact, robust, can be integrated in-line | Not a direct replacement for stylus profilers, sensitive to surface reflectivity and color |

| Atomic Force Microscopy (AFM) | Nanometer-level resolution | Very slow, limited measurement area, only suitable for a laboratory setting |

The Principle and Process of Laser Triangulation for Surface Measurement

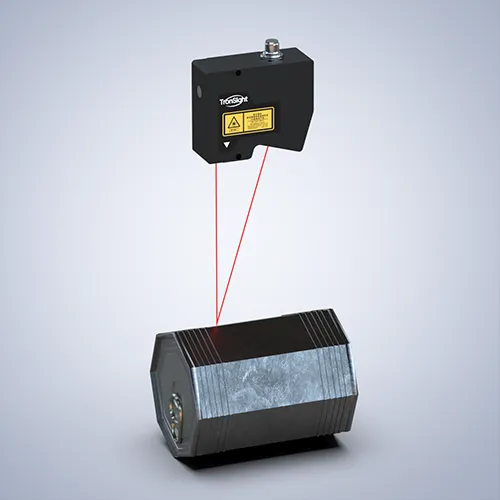

The Tronsight TS-P series laser triangulation displacement sensor provides a powerful solution for this challenge. Its principle is based on geometric optics. A laser beam is projected at a precise angle onto the metal surface. The light reflected from the surface is then captured by a receiving lens and focused onto a position-sensitive detector (PSD) or a CMOS/CCD array. As the surface height changes—even by tiny amounts—the position of the reflected light spot shifts on the detector.

The measurement process is both fast and precise:

-

Laser Projection: The sensor projects a focused laser line or spot onto the moving metal surface.

-

Light Reflection: The laser light reflects off the metal's surface, with its angle changing based on the surface's height variations.

-

Position Detection: The reflected light is captured by the sensor's lens and focused onto the detector. The detector pinpoints the exact position of the light spot.

-

Height Calculation: Based on the known triangulation geometry, the sensor's internal processor converts the light spot position into a precise distance measurement. By taking thousands of measurements in a short period as the part moves, the sensor creates a detailed profile of the surface, allowing for the calculation of roughness parameters like Ra or Rz.

Tronsight's Solution for Metal Surface Roughness Measurement

The Tronsight TS-P series laser triangulation displacement sensor is specifically designed to meet the demands of industrial metal surface inspection.

Key Features and Benefits:

-

Exceptional Speed: With a remarkable 160kHz sampling rate, the sensor can capture a vast amount of data points in real time, making it ideal for high-speed production lines.

-

High Precision: An outstanding ±0.02% of F.S. linear accuracy and 0.02μm repeatability ensure that your roughness data is highly precise and reliable.

-

Broad Measurement Range: A versatile measurement range from 2mm to 2000mm allows for the inspection of a wide variety of parts and materials.

-

Customizable Design: The TS-P series supports deep customization of line width, light source, wavelength, and structural dimensions. This flexibility allows us to tailor the sensor to your exact application needs.

-

Built-in Controller: The integrated controller simplifies setup and integration into existing systems, providing a robust, plug-and-play solution for automated inspection.

Our solution empowers you to perform high-speed, non-contact, and accurate roughness measurements, ensuring the quality and integrity of your metal components without slowing down your production process.

Learn More or Consult an Expert

-

Product Recommendations: See how the Tronsight TS-P series can enhance your surface roughness inspection.

-

Contact Us: Speak with one of our technical experts to get a customized solution for your specific application.

Leave a message:

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor