THIN FILM01.Mastering Ultra-Thin Film Thickness Measurement: A Guide to Advanced Sensing Solutions

Sep 09, 2025

The Critical Role of Ultra-Thin Films in Modern Industries

Ultra-thin films, with thicknesses ranging from just a few nanometers to several micrometers, are essential yet often overlooked components of modern technology. They form the foundation of countless high-tech products—from the anti-reflective coatings on smartphone displays and protective layers on solar panels to intricate layers in semiconductor devices.

The performance, durability, and functionality of these products rely heavily on the precise control of film thickness. In semiconductor manufacturing, even a deviation of a few nanometers can result in device failure. In optics, an incorrect coating thickness can compromise lens performance. Film thickness measurement is therefore not simply a quality-control step; it is a critical enabler of innovation, efficiency, and competitiveness.

Common Methods for Film Thickness Measurement

The choice of film thickness measurement method depends on film properties (transparency, reflectivity, and material type), the thickness range, and whether the process is performed in a laboratory or integrated in-line.

| Measurement Method | Pros | Limitations |

|---|---|---|

| Ellipsometry | Extremely high accuracy, non-contact, ideal for very thin films (<100 nm) | Complex setup, sensitive to surface conditions, relatively slow, rarely suitable for in-line use |

| Spectroscopic Reflectometry | Non-contact, fast, can be used in-line | Less accurate than ellipsometry, requires reflective surfaces |

| Contact Profilometry | High resolution, long-established | Destructive, time-consuming, risk of scratching films, only for laboratory use |

| Scanning Electron Microscopy (SEM) | Direct cross-sectional imaging | Destructive, expensive, requires vacuum environment, for R&D use only |

| Tronsight White Light Interferometry | Non-contact, high-speed, nanometer precision, in-line capable | Works best on transparent or semi-transparent films; not suitable for opaque materials |

| Tronsight Infrared Interferometry | Non-contact, high-speed, penetrates opaque/dark materials | Specialized for IR-transparent films, requires infrared illumination |

| Tronsight Reflective Interferometry | Non-contact, ultra-high precision, ideal for ultra-thin reflective films | Best suited for highly reflective coatings; not applicable to all materials |

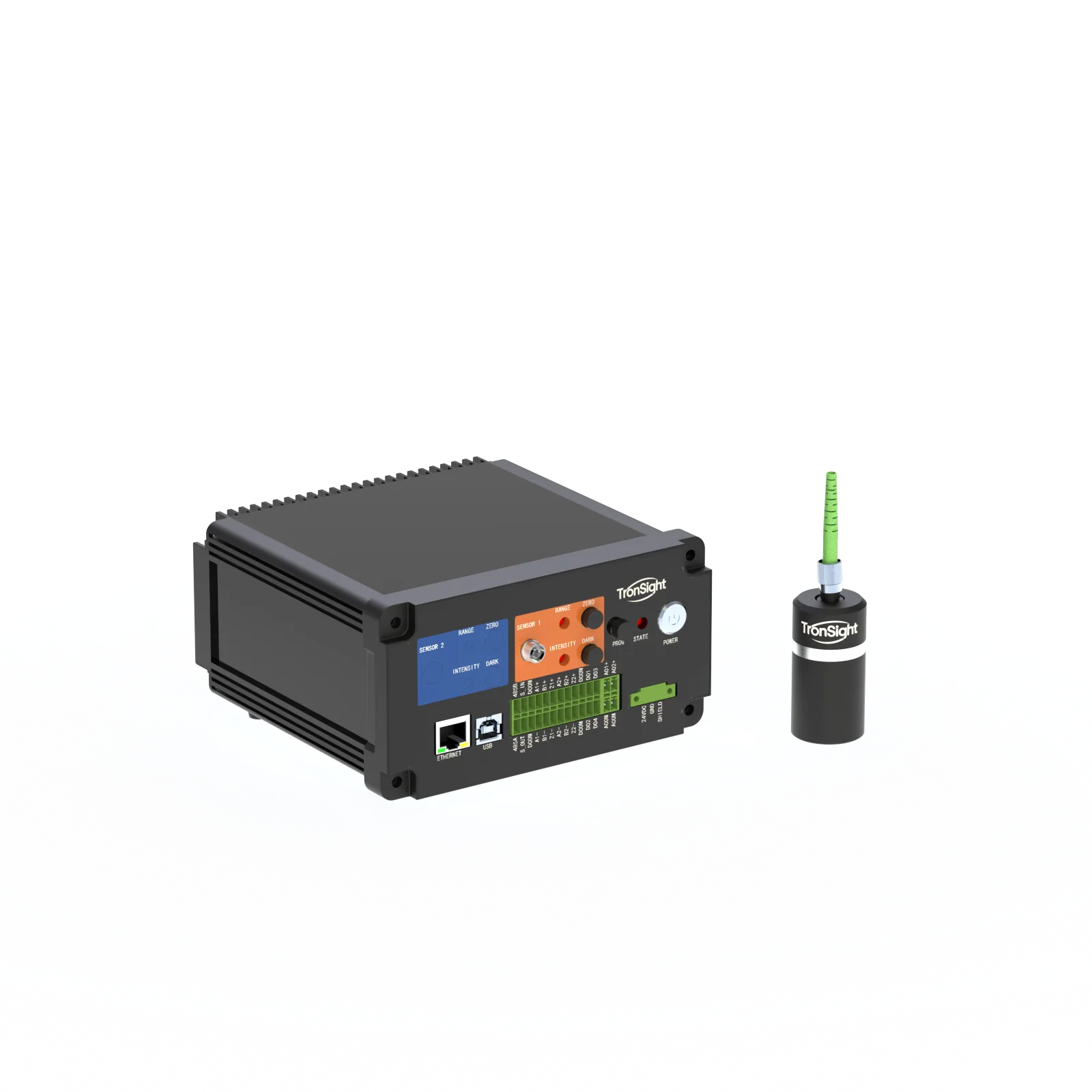

The Right Sensor for the Right Application: Tronsight’s Portfolio

Tronsight offers a complete portfolio of interferometric thickness sensors designed to address the diverse challenges of ultra-thin film measurement. Each series is optimized for specific materials and application scenarios.

TS-IV Series: White Light Interferometric Thickness Sensor

The TS-IV Series is the versatile choice for transparent and semi-transparent films. Leveraging broadband white light interferometry, it generates interference patterns from the top and bottom surfaces of a film to deliver precise thickness measurements.

Best For: Coatings, glass, anti-reflective layers, and multi-layer transparent structures (1–2500 μm).

Key Features:

-

1 nm repeatability – Ensures ultra-high precision in quality-critical applications.

-

±20 nm linear accuracy – Provides trustworthy measurement results.

-

Up to 10 kHz sampling speed – High-speed, in-line operation without compromising accuracy.

TS-IR Series: Infrared Interferometric Thickness Sensor

The TS-IR Series is purpose-built for semiconductor and opaque materials. Using infrared interferometry, it penetrates substrates that appear opaque in the visible spectrum but are transparent in the infrared range.

Best For: Semiconductor wafers (silicon, GaAs, SiC) and deeply colored or opaque films.

Key Features:

-

40 kHz sampling speed – Suitable for fast-moving production lines.

-

2 nm repeatability – Achieves the nanometer-level accuracy demanded by semiconductor processes.

-

Infrared penetration – Unlocks measurement capabilities for materials previously inaccessible to optical methods.

TS-R Series: Reflective Film Thickness Sensor

The TS-R Series is the specialist for ultra-thin, highly reflective films, designed to push the boundaries of precision. Using reflective interferometry, it achieves unparalleled resolution and measurement stability.

Best For: Optical coatings, metallic films, and semiconductor layers with sub-100 nm thicknesses.

Key Features:

-

Minimum measurable thickness: 20 nm – Expands the lower limit of thin-film measurement.

-

±1 nm accuracy, 0.05 nm repeatability – Exceptional stability for critical process control.

-

Up to 100 Hz sampling speed – Delivers real-time feedback for production optimization.

Tronsight: Your Partner in Precision Metrology

Selecting a Tronsight sensor means more than acquiring advanced hardware. It means collaborating with a team of experts who understand your process challenges and support seamless integration.

Our interferometric sensors combine non-contact, high-speed operation with nanometer precision, ensuring that your production line achieves both efficiency and reliability.

Learn More or Consult an Expert

-

Product Recommendations: Explore the TS-IV, TS-IR, and TS-R Series.

-

Contact Us: Speak with an expert to get tailored solutions for your application.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor