【Industry Application】Laser Displacement Sensor Measures Thickness of Lithium Battery Electrode Tabs

Sep 25, 2023

1.Introduction

As the electric vehicle market continues to expand, the demand for lithium batteries is increasing. During the production process of lithium batteries, the thickness of the electrode is one of the important factors affecting the performance and safety of the battery. Therefore, precise thickness measurement of lithium battery electrodes is a key link in the production process. In recent years, laser displacement sensors, as high-precision measuring devices, have been widely used in the thickness measurement of lithium battery electrodes. This article will introduce the working principle, application scenarios, measurement methods, experimental results, and the application prospects of laser displacement sensors in the thickness measurement of lithium battery electrodes.

2.Principle

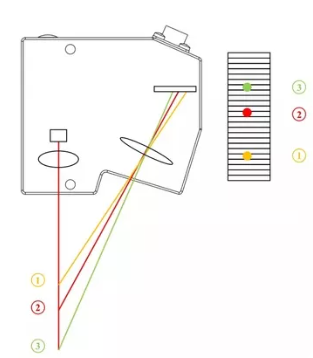

A laser displacement sensor is a measuring device based on optical principles. It emits a laser beam and receives the laser beam reflected back from the object being measured, measuring the displacement change of the laser beam on the surface of the object, thereby calculating the surface profile and thickness of the object. Compared with traditional contact measurement methods, laser displacement sensors have the advantages of non-contact, high precision, and rapid measurement. In the thickness measurement of lithium battery electrodes, laser displacement sensors can effectively avoid scratches and deformations caused by contact, improving measurement accuracy and production efficiency.

In the thickness measurement of lithium battery electrode sheets, laser displacement sensors can achieve high-precision measurement of the sheet thickness and also detect the surface profile of the sheets, providing strong support for quality control during production.

Measurement Method

The specific measurement method of laser displacement sensors in the thickness measurement of lithium battery electrode sheets is as follows:

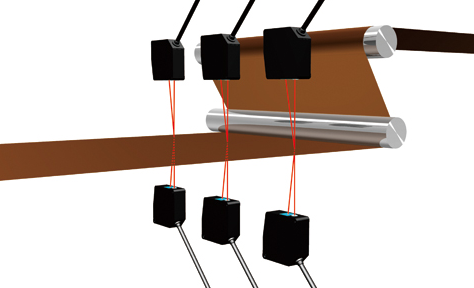

Thickness Measurement: First, fix the laser displacement sensor on the test bench and adjust its distance from the sheet to be measured to ensure that the laser beam can correctly illuminate the surface of the sheet. Then, through the operation of the control system, the laser displacement sensor scans the sheet and records the displacement data of each point. By processing and analyzing the displacement data, the thickness distribution of the sheet can be obtained.

Precision Calibration: To ensure measurement accuracy, regular precision calibration of the laser displacement sensor is required. Generally, a standard reference block can be used for calibration. Place the standard reference block on the test bench, adjust the position relationship between the laser displacement sensor and the reference block, so that the laser beam can illuminate the surface of the reference block vertically. Then, through the operation of the control system, the laser displacement sensor scans the reference block and records the displacement data. By analyzing and processing these data, the accuracy error of the sensor can be obtained, and corresponding adjustments and compensations can be made.

Stability Test: To ensure the reliability of the measurement results, it is also necessary to regularly test the stability of the laser displacement sensor. Generally, long-term monitoring can be used for stability testing. Place the laser displacement sensor on the test bench, scan a fixed object to be measured, and record the measurement data over a period of time. By analyzing and processing these data, the stability error of the sensor can be obtained, and corresponding adjustments and compensations can be made.

Result Analysis

Through experimental results and analysis, we found that the laser displacement sensor has the following advantages in measuring the thickness of lithium battery electrodes:

High precision: The precision of the laser displacement sensor can reach the micron level or even higher, allowing for high-precision measurement of the thickness of lithium battery electrodes.

Non-contact: The laser displacement sensor uses a non-contact measurement method, avoiding scratches and deformation issues caused by contact, and can also effectively prevent measurement errors caused by contact.

Rapid measurement: The measurement speed of the laser displacement sensor is very fast, allowing for the measurement of a large number of samples in a short time, greatly improving production efficiency.

High degree of automation: The laser displacement sensor can be used in conjunction with automated production lines, achieving automated measurement and data collection, reducing labor costs and error rates.

Conclusion

This article introduces the application of laser displacement sensors in measuring the thickness of lithium battery electrodes. Through experimental results and analysis, we found that laser displacement sensors have advantages such as high precision, non-contact, and rapid measurement, making them suitable for the production process of measuring the thickness of lithium battery electrodes. At the same time, we also found that the application prospects of laser displacement sensors are very broad, and they can be widely applied in more fields in the future. Therefore, we believe that laser displacement sensors will become one of the important technologies for future industrial inspection and control.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)