【Industry Application】Spectral Confocal Quad-Point Sensor Head Height Measurement of Meniscus Lens Repeatability

Nov 21, 2023

Abstract: Due to its unique advantages such as high precision, allowing for a greater tilt angle of the measured surface, fast measurement speed, high real-time performance, low requirements for the condition of the measured surface, and high resolution, spectral confocal measurement technology has rapidly become a popular sensor in industrial measurement. It has been widely applied in fields such as biomedicine, materials science, semiconductor manufacturing, surface engineering research, precision measurement, and 3C electronics.

Introduction

In the previous article, we introduced the repeatability measurement of biconcave lenses. This time, we will measure the repeatability of meniscus lenses to verify whether the probe can effectively and stably measure lenses with different material shapes and thicknesses. The measurement requirements and methods are the same as those for measuring biconcave lenses.

The TS-C4000F spectral confocal sensor head and CCS controller from Chuangshi Intelligent. The TS-C series spectral confocal displacement sensors can achieve a repeatability precision of 0.025µm, a linear precision of ±0.02% of F.S., a maximum sampling speed of 30kHz, and a measurement angle of ±65°, which can adapt to surfaces such as mirrors, transparent, semi-transparent, film layers, rough metal surfaces, and multi-layer glass, supporting data transmission interfaces like 485, USB, Ethernet, and analog.

Measurement Scenario

1 Measurement Requirements and Methods

Measurement Requirements:

Test sample: Meniscus lens

1.After pneumatic adsorption of the lens, the pneumatic claw positions the lens multiple times to achieve centering based on the outer circle of the lens.

2.Use the sensor to measure the center height of the lens.

3.Rotate the lens to different angles for repeated measurements.

4.The deviation between multiple measurement results should be less than 2um.

Measurement Method:

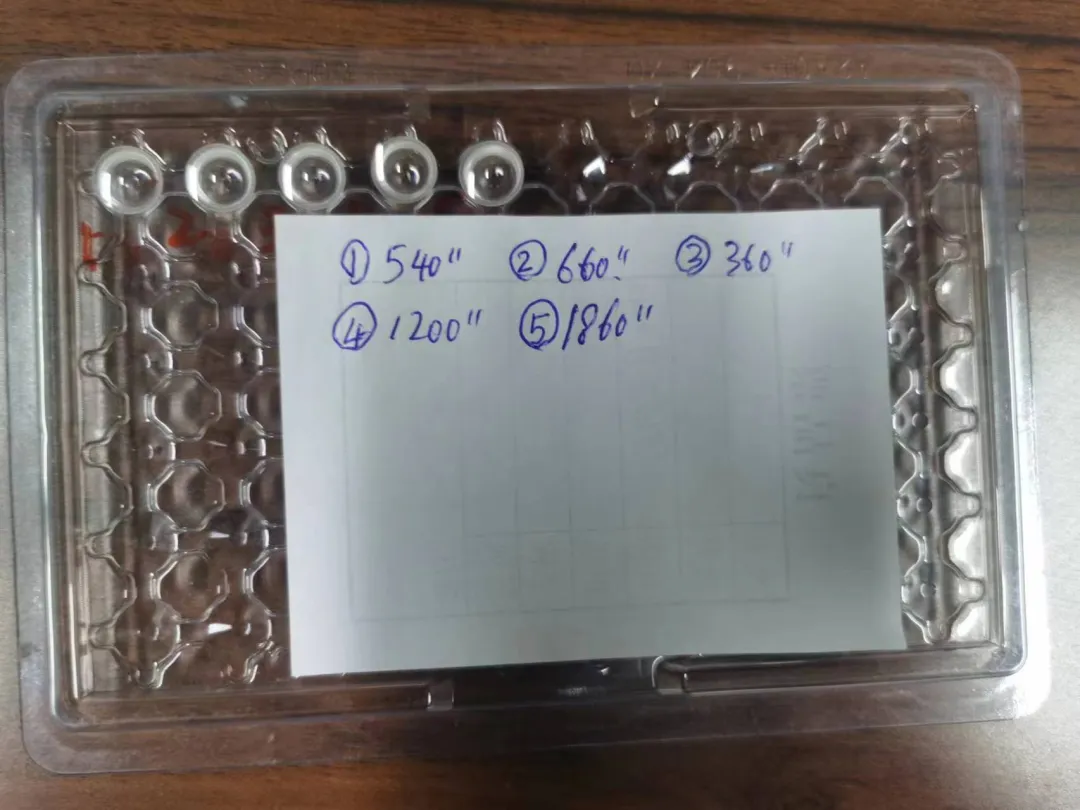

1.Measure 3 lenses sequentially.

2.Rotate the lens to different angles to achieve multiple measurements of the same lens.

3.Compare the measurement results.

2 Measurement Results Analysis

Using a four-light-point probe and taking the extreme value as the final lens height measurement method can be applied to eccentric lenses and yields better results than using the average value.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)