3C01.CMOS Assembly Height Measurement

Jul 30, 2025

Why It Matters

In CMOS image sensor manufacturing, the precise alignment and height of individual components—such as lens holders, filters, and sensor chips—play a crucial role in ensuring image quality and performance. Inaccurate height or tilt during assembly can lead to focus drift, optical aberrations, or even sensor failure. Therefore, accurate non-contact height measurement is essential to maintain tight tolerances and improve production efficiency.

Common Measurement Methods

| Method | Contact/Non-contact | Accuracy | Suitability for CMOS Components | Limitations |

|---|---|---|---|---|

| Contact Probe | Contact | Moderate | Limited | May damage sensitive parts |

| Laser Displacement Sensor | Non-contact | High | Good | Affected by reflective materials |

| Chromatic Confocal Sensor | Non-contact | Very High | Excellent | Higher cost |

Measurement Principle & Procedure

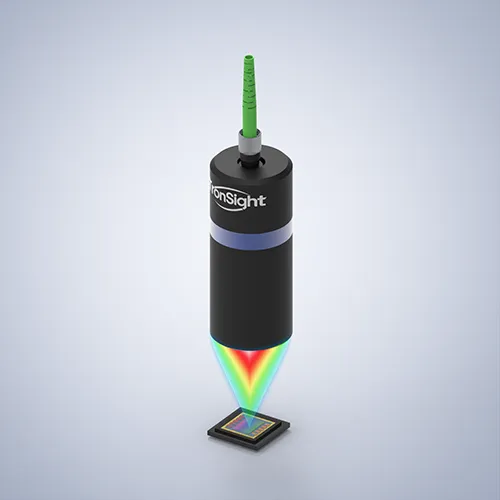

Chromatic Confocal Displacement Sensors (like TS-C Series) utilize chromatic dispersion to determine height by detecting the focal wavelength of reflected light. Each wavelength focuses at a different height, and the peak signal corresponds to the surface position.

Steps:

-

Mount the CMOS unit on a precision platform.

-

Scan across target components (e.g., lens holder, sensor die).

-

Collect height data for multiple points.

-

Analyze parallelism and height difference to ensure assembly standards.

This method is ideal for micron-level control and real-time feedback in high-volume production lines.

TronSight’s Solution

TronSight’s TS-C series chromatic confocal sensors offer superior vertical resolution (up to 5 nm) and high sampling rates (up to 30 kHz), enabling accurate inspection of component heights, step profiles, and flatness in CMOS sensor modules.

Advantages:

-

Works with various transparent and reflective materials

-

Immune to ambient light interference

-

High precision for multilayer structures

Recommended Product

👉 TS-C Series Chromatic Confocal Displacement Sensor

Accurate, stable, and contactless measurement for semiconductor and optical applications.

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

.webp?x-oss-process=image/resize,w_100/quality,q_100)