AUTO02.Liquid Level Height Measurement with Chromatic Confocal Sensors

Sep 08, 2025

1. What It Is & Why It Matters

Liquid level height measurement refers to monitoring and quantifying the height of liquid surfaces in tanks, pipelines, or process chambers. Accurate liquid level monitoring is critical in industries such as:

-

Batteries & new energy – precise electrolyte control ensures performance and safety.

-

Semiconductor & display manufacturing – stable liquid levels improve process consistency.

-

Pharmaceutical & food industries – accurate liquid handling ensures quality and hygiene.

Consistent and precise level measurement helps prevent overflow, shortage, and process instability, ensuring safety, efficiency, and quality assurance.

2. Common Measurement Methods

| Method | Principle | Advantages | Limitations |

|---|---|---|---|

| Float-based sensor | Float moves with liquid surface | Simple, low cost | Limited precision, mechanical wear |

| Ultrasonic sensor | Measures echo time of sound waves | Non-contact, works in opaque liquids | Accuracy affected by bubbles, turbulence |

| Capacitance sensor | Detects dielectric change in liquid | Compact, continuous measurement | Sensitive to liquid type and conductivity |

| Chromatic confocal sensor | Focus shift of polychromatic light | Non-contact, high accuracy, works on transparent or reflective liquids | Requires optical alignment |

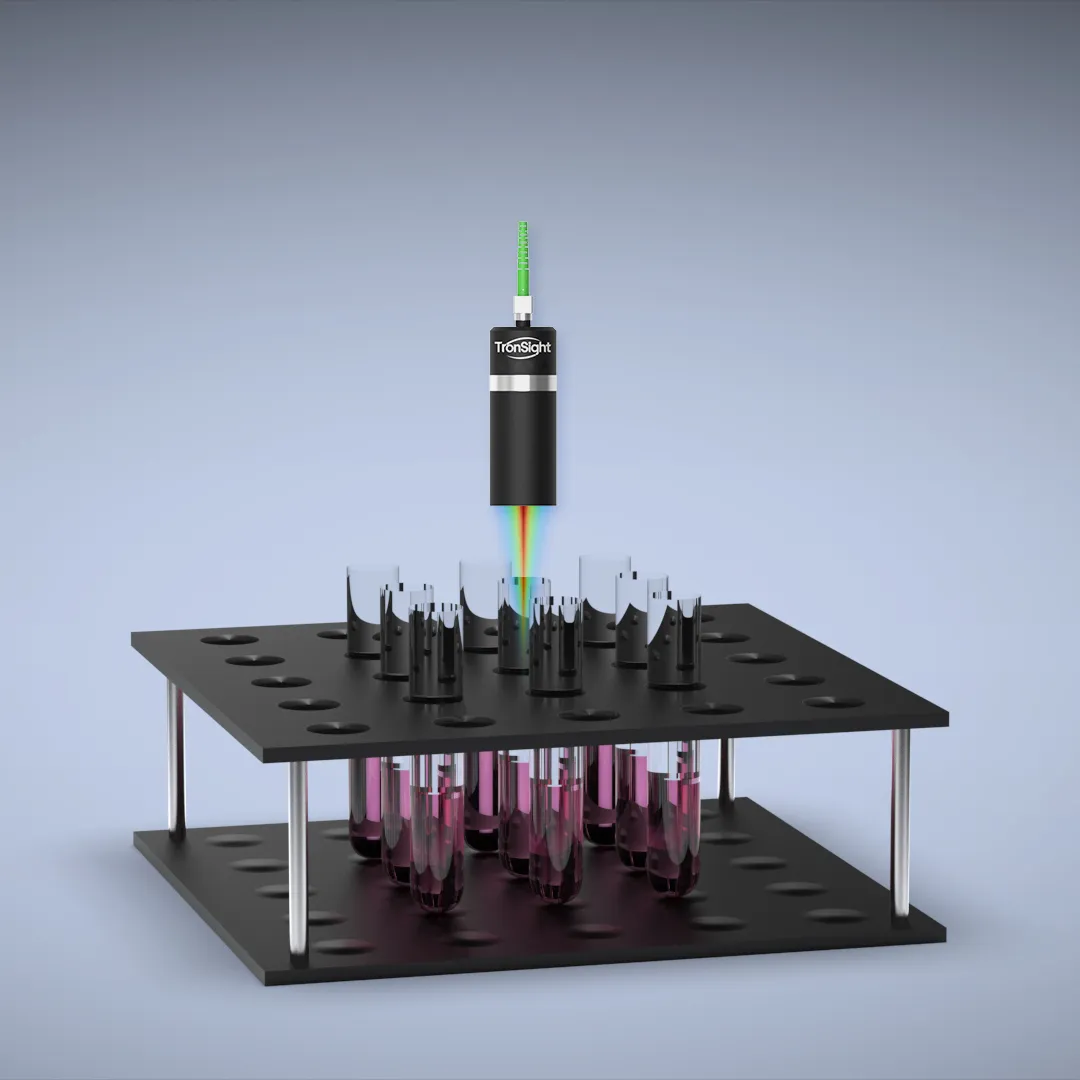

3. Principle & Process of Chromatic Confocal Measurement

A chromatic confocal displacement sensor projects a broad-spectrum light through a lens. Different wavelengths focus at different depths. When the reflected light returns, the sensor determines the exact focal wavelength, corresponding to the distance to the liquid surface.

Key benefits for liquid level applications:

-

Non-contact measurement – no contamination of liquid.

-

High resolution & accuracy – detects subtle level changes.

-

Handles transparent or reflective liquids reliably.

-

Works in extreme environments – supports high temperature and vacuum conditions.

4. TronSight’s Solution

The TronSight TS-C Series Chromatic Confocal Displacement Sensor is well-suited for liquid level height measurement:

-

32kHz maximum sampling speed – enabling fast and stable detection.

-

16-channel synchronous measurement – multi-point monitoring for precision.

-

Compact probes (down to Ø3.8mm) – suitable for narrow or complex containers.

-

+60° maximum measurement angle – handles tilted or curved surfaces.

-

Compatible with high-temperature and vacuum environments.

-

Capable of measuring transparent or multi-layer liquid surfaces.

Application Example (conservative wording):

In liquid level monitoring, the TS-C sensor measures the distance to the liquid surface without contact, providing real-time data for process monitoring and quality assurance.

5. Product Recommendation & Contact

Recommended Product:

👉 TS-C Series Chromatic Confocal Displacement Sensor

Key Features:

-

32kHz sampling speed

-

16-channel synchronous acquisition

-

Ø3.8mm minimum probe diameter

-

+60° measurement angle

-

High-temp & vacuum compatibility

📩 Contact Our Experts

-

Email: sales@tronsight.com

-

Phone/WeChat/WhatsApp: +86 13737266828

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor