AUTO01.Stamping Stroke Measurement with Laser Triangulation Sensors

Aug 29, 2025

1. What It Is & Why It Matters

Stamping stroke measurement refers to monitoring the displacement of stamping press tools during metal forming. Accurate stroke measurement ensures:

-

Production consistency – guaranteeing each part meets dimensional tolerances.

-

Tool protection – detecting abnormal strokes to prevent press and die damage.

-

Process optimization – enabling closed-loop feedback for press automation.

-

Quality assurance – reducing defective parts and material waste.

In high-speed stamping lines, precise and non-contact stroke monitoring is crucial for efficiency, safety, and yield improvement.

2. Common Measurement Methods

| Method | Principle | Advantages | Limitations |

|---|---|---|---|

| Mechanical LVDT sensor | Coil-based linear displacement sensing | Mature, relatively low cost | Contact wear, limited bandwidth |

| Linear encoder | Optical grating displacement detection | High resolution, stable | Sensitive to dust, vibration |

| Laser interferometry | Optical interference of laser beam | High accuracy | Complex setup, costly |

| Laser triangulation sensor | Measures reflection angle shift of laser | Non-contact, high-speed, robust on metals | Accuracy depends on surface reflectivity |

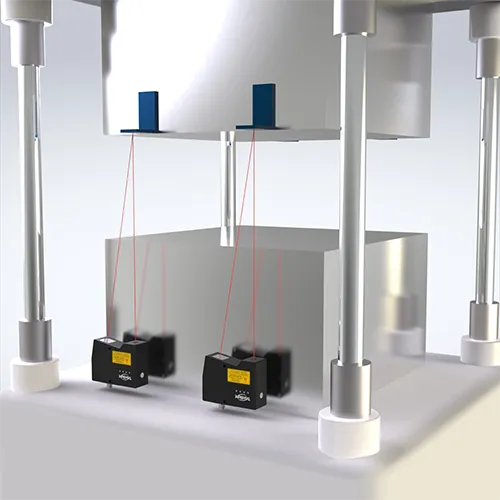

3. Principle & Process of Laser Triangulation Measurement

Laser triangulation displacement sensors measure stamping stroke by:

-

Projecting a laser beam onto the moving press tool or workpiece.

-

Receiving the reflected light with a position-sensitive detector.

-

Calculating stroke displacement based on the triangulation geometry.

-

Tracking motion at high speed for real-time stroke curves.

Key benefits for stamping applications:

-

Non-contact measurement, avoiding wear and impact.

-

High-speed response (160kHz) for fast stamping presses.

-

Micron-level precision (0.02μm repeatability) for detailed analysis.

-

Inline integration, enabling automatic monitoring and alarm functions.

4. TronSight’s Solution

The TronSight TS-P Series Laser Triangulation Displacement Sensor provides a robust solution for stamping stroke measurement:

-

160kHz sampling rate – suitable for high-speed stamping lines.

-

±0.02% of F.S. linear accuracy – ensuring reliable stroke data.

-

0.02μm repeatability – capturing micro stroke variations.

-

Measuring range: 2–2000mm – adaptable to small and large presses.

-

Customizable (laser wavelength, spot size, structural design).

-

Integrated controller – reducing installation complexity.

Application Example (conservative wording):

In stamping lines, TS-P sensors can measure real-time stroke displacement, providing feedback for press adjustment and helping detect stroke anomalies before defects occur.

5. Product Recommendation & Contact

Recommended Product:

👉 TS-P Series Laser Triangulation Displacement Sensor

Key Features:

-

160kHz sampling rate

-

±0.02% F.S. accuracy

-

0.02μm repeatability

-

2–2000mm measuring range

-

Integrated controller

📩 Contact Our Experts

-

Email: service@tronsight.com

-

Phone/WeChat/WhatsApp: +86 13737266828

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor