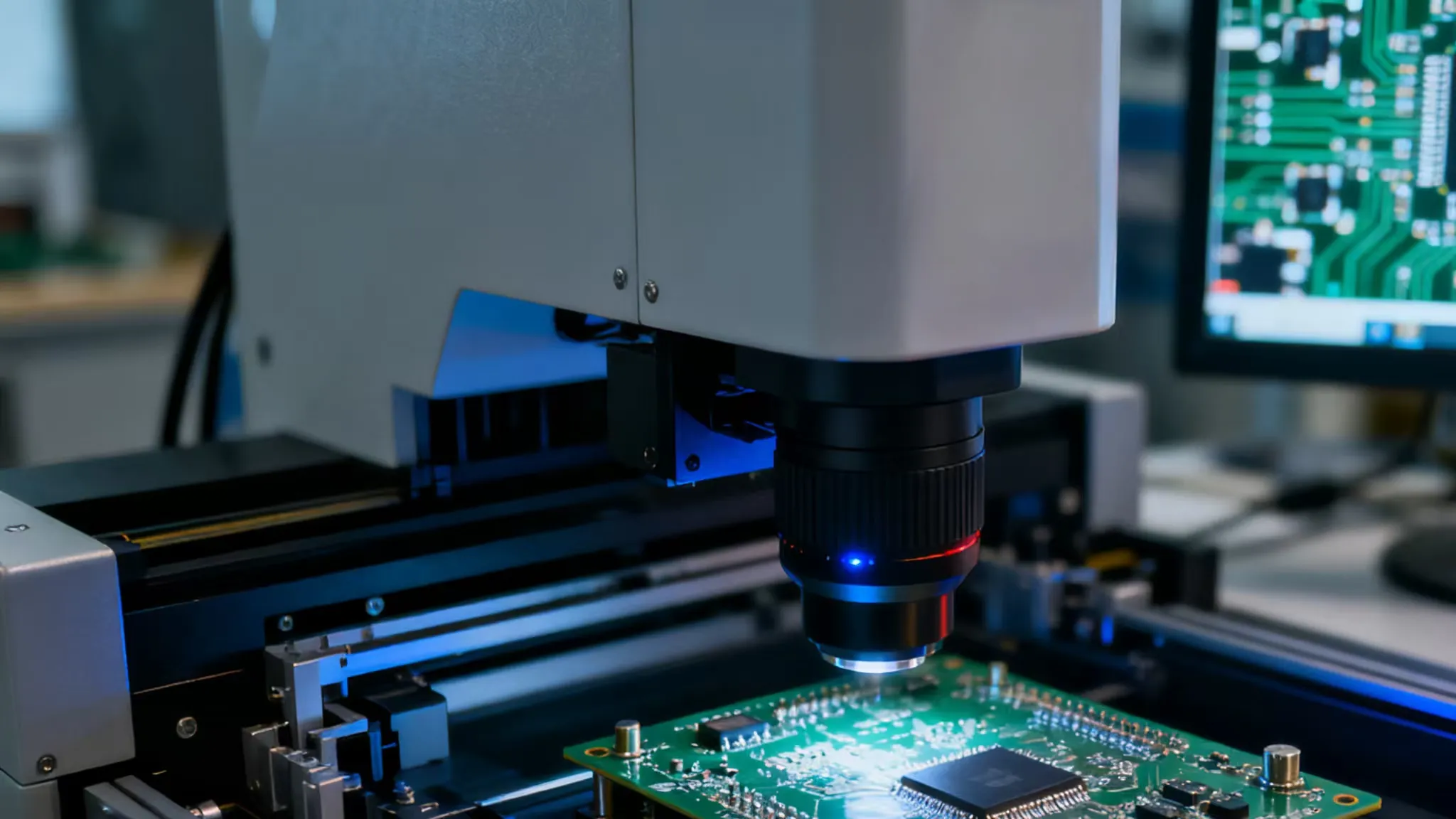

TS-AF Series Coaxial Real-Time Autofocus Module | High-Speed Focus Solution for AOI Systems

Jul 29, 2025

In microscopic automated optical inspection (AOI), achieving and maintaining sharp focus is a constant challenge. Traditional autofocus mechanisms often struggle when dealing with high-magnification lenses, reflective or transparent surfaces, or rapidly changing topographies. This is where real-time autofocus (RTAF) steps in—not as a luxury, but as a necessity.

Why Traditional Autofocus Falls Short

Conventional autofocus methods rely on image contrast or stepwise focusing, which can be slow, imprecise, and prone to drift. In high-volume manufacturing environments—such as semiconductors, flat panels, AR/VR optics, and 3C electronics—this leads to significant inefficiencies. A momentary loss of focus can result in missed defects, lower yields, or costly re-inspections.

Research in semiconductor AOI systems confirms that focus errors directly degrade defect detection accuracy and throughput (Lee et al., 2019). At advanced technology nodes, even sub-micron defocus can compromise overlay and CD uniformity (Huang et al., 2017).

| Method | Principle | Features | Applications |

|---|---|---|---|

| Contrast AF | The Z-axis moves slightly back and forth to find the position with the highest image contrast (sharpness). | High precision; intuitive contrast evaluation; relatively slow. | Microscopy imaging, high-precision inspection. |

| Stepping AF | The Z-axis moves step by step, capturing an image at each step, then selecting the sharpest one as the focus. | Stable results; clear algorithm; moderate speed. | Industrial inspection, automated imaging, optical testing. |

| AOI AF (Area of Interest AF) | Calculates sharpness only within a defined Area of Interest (AOI) and focuses on that region. | Faster focusing; optimized for specific regions; robust in complex backgrounds. | Semiconductor inspection, PCB inspection, defect detection. |

The Case for Real-Time Autofocus

Real-time autofocus operates at tens of kilohertz frequencies, continuously adjusting focus without interrupting the inspection flow. This ensures that even under dynamic Z-axis motion or when scanning across warped/uneven samples, the imaging system remains in perfect sharpness.

In AOI, this translates to:

-

Higher defect detection rates

-

Stable imaging across reflective, transparent, and multi-layered samples

-

Reduced downtime and improved throughput

.gif)

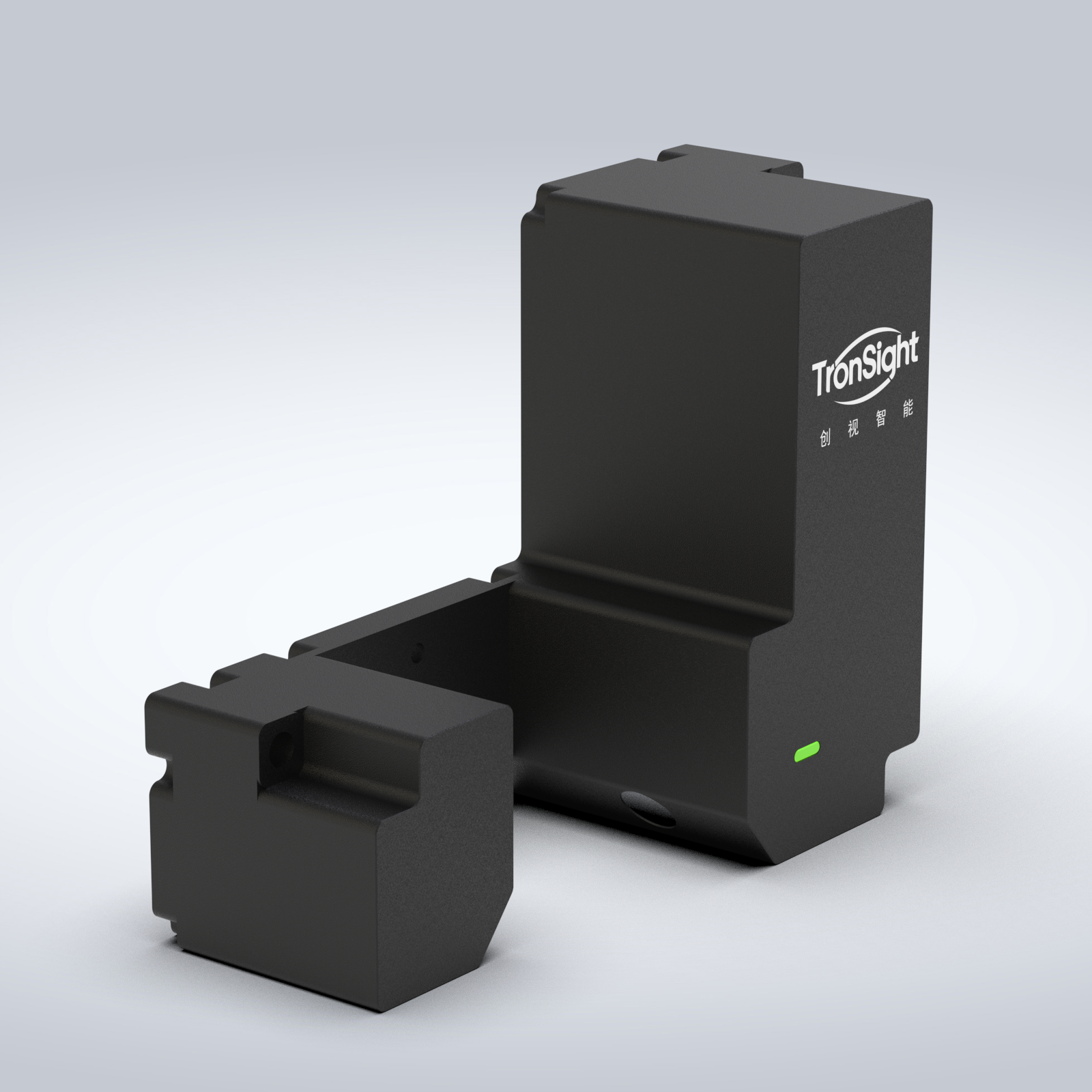

TronSight TS-AF Series: Engineered for High-Speed Precision

TronSight’s TS-AF series real-time autofocus module, derived from the TS-P series of laser triangulation displacement sensors, is purpose-built for next-generation AOI challenges. Designed as a split-type module, it is fully compatible with over 98% of objective lenses and industrial microscopes available in the market.

Key specifications include:

-

Defocus detection resolution: 10 nm

-

Autofocus precision: ±0.5 μm

-

Autofocus speed: up to 160 kHz

-

High-magnification support: enabling stable imaging at high resolution

Product Models

| Parameter | TS-PD08 | TS-PD15 |

| Reference Distance | 8 mm | 15 mm |

| Measurement Range | ±0.8 mm | ±1 mm |

| Spot Diameter | 20 µm | 35 µm (or 35 × 1000 µm) |

| Repeatability | 0.03 µm | 0.05 µm |

| Sampling Frequency | Up to 160 kHz | Up to 160 kHz |

Applications Across Industries

The TS-AF series addresses diverse AOI needs in the pan-semiconductor sector:

-

Semiconductors: wafer surface and defect inspection under advanced nodes

-

Flat panels: large-area glass inspection with stable high-speed focusing

-

AR/VR: precision lens surface and coating inspection under high magnification

-

3C electronics: micro-defect detection in compact assemblies

By ensuring nanometer-level focusing accuracy at kilohertz speeds, TS-AF empowers manufacturers to achieve both throughput and precision—critical for today’s competitive markets.

Conclusion

In microscopic AOI, real-time autofocus is non-negotiable. Traditional approaches cannot keep pace with the demands of high-throughput, high-magnification inspection. TronSight’s TS-AF series provides the speed, precision, and compatibility required to maintain focus stability across semiconductor, display, AR/VR, and 3C applications.

With nanometer-level defocus resolution, sub-micron accuracy, and up to 160 kHz speed, TS-AF ensures that manufacturers can capture every detail without compromise.

TronSight — Precision Measurement Expert

References

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor