SEMI05.Adjustment of Wafer Conveyor Systems

Jul 30, 2025

Why It Matters

In semiconductor production lines, wafer conveyor systems serve as a critical component for transferring delicate wafers between process stations. Any misalignment, tilt, or vibration in these conveyor systems may lead to mechanical stress, wafer edge chipping, or mispositioning, ultimately compromising yield and causing substantial equipment downtime.

Accurate adjustment of wafer conveyors is essential to:

-

Maintain wafer planarity during high-speed movement

-

Prevent collision or misalignment with robot arms

-

Ensure precise positioning in lithography or etching stages

-

Optimize throughput without sacrificing accuracy

To achieve these goals, non-contact, high-precision displacement sensors are required to monitor position, angle, and height variations of conveyor elements in real-time.

Common Measurement Methods for Conveyor Adjustment

| Method | Principle | Pros | Cons |

|---|---|---|---|

| Mechanical Gauges | Contact-based height comparison | Simple, low-cost | Not precise enough for sub-micron alignment |

| Vision Systems | Image-based alignment checking | Can monitor multiple axes simultaneously | Sensitive to ambient light & surface finish |

| Laser Displacement Sensors | Triangulation | High precision, fast response | Requires calibration, careful setup |

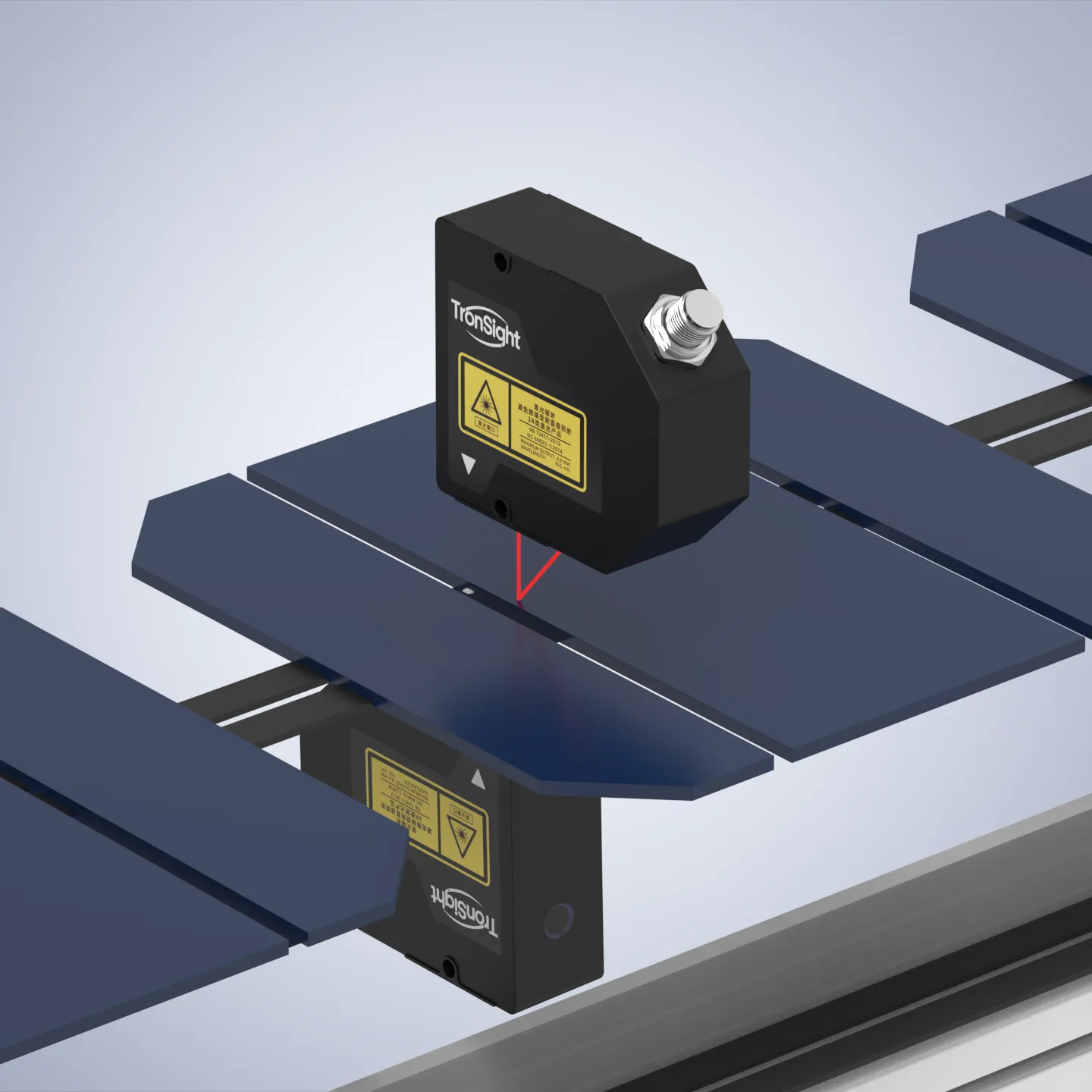

Measurement Principle & Process

Laser triangulation displacement sensors measure the vertical position of conveyor rollers, rails, or belts by emitting a focused laser beam and calculating the reflected angle. By installing multiple sensors across key positions, engineers can:

-

Determine rail or roller flatness

-

Identify tilt or angular deviation

-

Realign conveyor surfaces based on real-time feedback

-

Establish tolerance zones and set alarms for deviation

For dynamic tuning, sensors can be integrated into automated alignment systems that adjust servo drives or pneumatic stages during commissioning or maintenance cycles.

Tronsight’s Solution

Tronsight offers a cost-effective and high-performance solution for wafer conveyor adjustment using the TS-P series laser displacement sensors.

-

TS-P30 delivers ±0.02% of F.S. linearity, 0.02μm repeatability, and sampling rates up to 160kHz.

-

Ideal for dynamic tracking of conveyor surfaces during real-time motion.

-

Compact and rugged design enables easy integration even in tight production environments.

Users can deploy multiple TS-P30 sensors across conveyor axes and feed data into PLC or motion controllers for automated adjustment or closed-loop feedback.

Recommended Product

TS-P30 Laser Displacement Sensor←Click for more details

Short-range, ultra-high repeatability, compact and cost-efficient. Ideal for precision positioning and adjustment of semiconductor conveyor systems.

Contact us

📨Click to send a message

📞 WhatsApp / WeChat: +86 13737266828

📧 Email: service@tronsight.com

Recent Posts

October 26, 2016

The Most Successful Engineering Contractor

.webp?x-oss-process=image/resize,w_100/quality,q_100)